heat treatment

Provides the raw inserts with the required hardness, resistance to corrosion and elastic response to vibrations.

Surgical inserts are made of medical grade stainless and undergo a production process guaranteeing their quality. Inserts vibrate at 36,000 micro-vibrations/sec. and can stand the huge mechanical forces they are exposed to during surgeries.

Provides the raw inserts with the required hardness, resistance to corrosion and elastic response to vibrations.

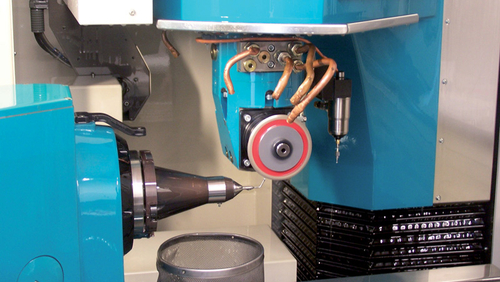

The automatic 5-axis CNC grinder cuts with a precision up to 0.1 µm. Based on indications for use, specific treatments are performed on the insert surface, including diamond coating with diamonds in different grain sizes.

Each insert is laser-marked. The code is engraved in the insert's stem for higher security.

Each insert undergoes quality controls during the production process. Checks range from a dimensional control on the semi-finished product to the control of sterilised inserts before packaging.

Surgical inserts of different shapes and dimensions, curved and angled, designed to perform osteotomies with the utmost safety even in difficult to reach surgical sites.

Surgical inserts curved and angled, with sharp edges, for bone modelling and bone chip harvesting.

Surgical insert tips assembly